INNOVATION LAB

Every solution we build starts with a clear goal: to meet the customer’s exact needs, not just industry standards. Our in-house systems are fully customized, designed, tested and deployed with precision to solve real-world challenges.

Bespoke Power Solutions

In today’s market, most power supplies are designed to deliver clean, uninterrupted energy. Our bespoke solutions take a different approach: we engineer custom power interrupter systems that replicate real‑world conditions exactly as specified by our customers.

This capability is already being applied in the aerospace industry, where flight hardware must be tested against sudden power interruptions to validate resilience and safety. By simulating controlled disruptions, we help aerospace and advanced technology partners ensure their systems perform reliably under the most demanding conditions.

Data Analytics: Turning Logs into Insights

Our team leverages advanced analytics to move beyond firefighting and into prevention. Using Python, we extract and process BLU log data to identify recurring issues such as constant jams. These insights are then visualized through Power BI dashboards, giving real‑time visibility into problem areas and trends.

By applying Six Sigma methodologies, we don’t just highlight issues — we design corrective and preventive solutions that eliminate root causes, improve process stability, and enhance overall efficiency. This approach transforms raw data into actionable intelligence, helping our customers achieve consistent performance and long‑term reliability.

Predictive Maintenance: Anticipating Issues Before They Happen

We harness the power of Python analytics to transform raw motor log data into actionable insights. By continuously monitoring torque and current patterns, our system detects anomalies that signal potential failures long before they occur. This predictive approach allows us to forecast maintenance needs with precision, ensuring parts and resources are prepared in advance.

The benefits are clear:

-

Lower Downtime: Equipment stays online longer with fewer unexpected stoppages.

-

Proactive Planning: Spare parts and service schedules are aligned with actual wear patterns.

-

Cost Efficiency: Prevents costly emergency repairs and extends asset life.

-

Reliability: Builds confidence in systems used across automotive, semiconductor, and aerospace industries.

-

By combining data science with engineering expertise, we move beyond reactive firefighting to a smarter, preventive model — keeping operations resilient and future‑ready.

Smart Monitoring & Control Platform

Our innovation brings powerful connectivity and real-time insights together in one intuitive platform. With multi-channel support, built-in humidity calculations, live charting and automated recording, it turns complex sensor data into clear, actionable dashboards.

Flexible exports, proactive maintenance alerts and a customizable interface ensure reliability and ease of use — helping you monitor smarter, catch issues before they escalate and stay ahead with confidence.

Custom Video Monitoring, Built Around Your Process

Quality issues don’t wait — and neither should your visibility. Our tailored video feed monitoring system is designed to integrate seamlessly into complex automation environments, from inside semiconductor machines to overhead transfer lines.

By combining trusted camera technology with a fully customized feed layout, we give engineers real‑time insight into every critical stage of production.

The result: faster root‑cause detection, reduced downtime, and a clear, unbiased view that eliminates finger‑pointing between teams.

With flexible configuration and scalable design, our solution adapts to your workflow, ensuring you see exactly what matters most.

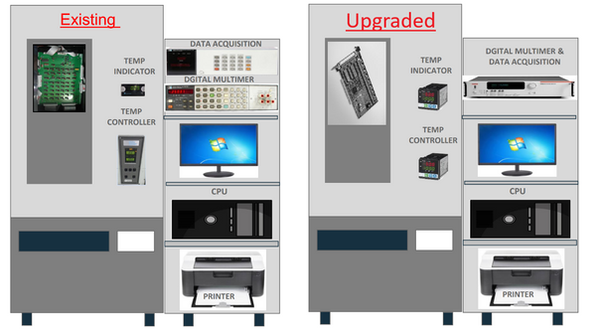

Retrofitting Legacy Hardware with Next-Gen Intelligence

This project began with a simple request: breathe new life into an aging oven system. While the external shell remained untouched, every internal component was rebuilt from the ground up. We replaced legacy PCBs, software and interface modules with modern equivalents specifications—delivering enhanced precision, reliability, and control.

The result is a fully customized solution that preserves the original form factor while unlocking the performance of a brand-new system, tailored entirely to the customer’s operational needs.